Blog Entry

PIC18 Pulse Width Modulation (PWM) DC Motor Speed Controller with the RPM Counter Project

December 9, 2009 by rwb, under Microcontroller.

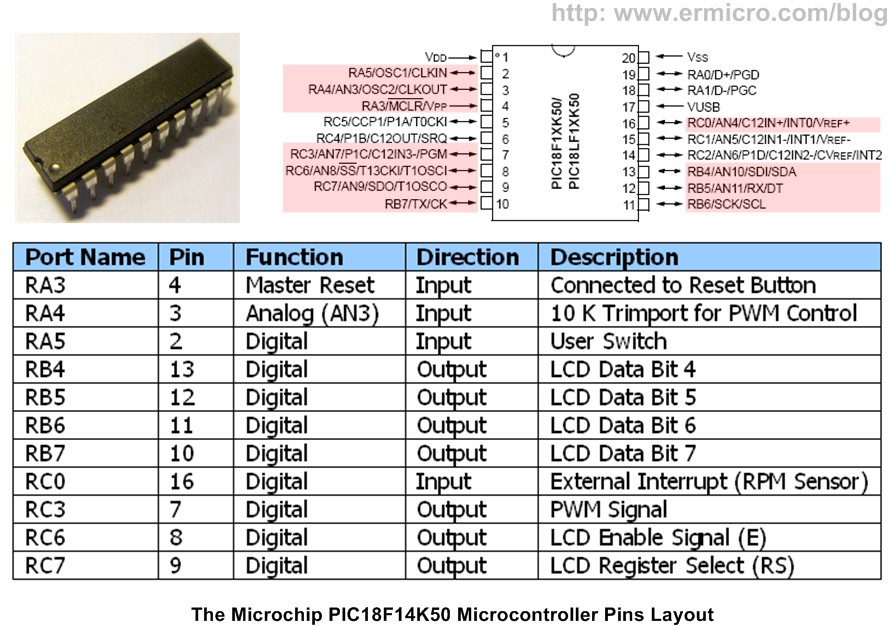

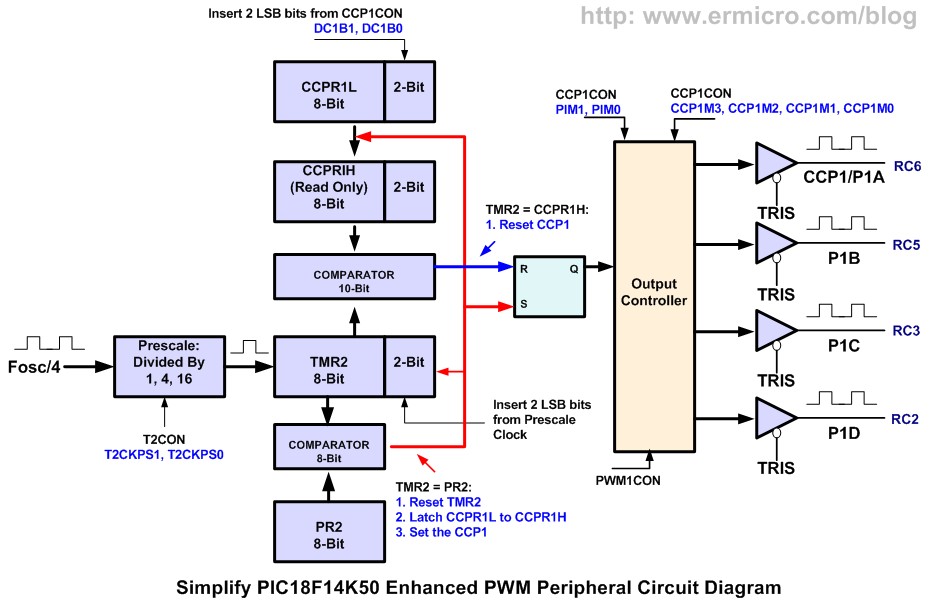

Equipped with sophisticated Enhanced Capture/Compare/PWM (ECCP) peripheral the Microchip PIC18F14K50 microcontroller could produce up to four PWM channels output. The enhanced PWM (Pulse Width Modulation) mode in ECCP peripheral is capable to drive the full bridge DC Motor circuit directly both in forward or reverse direction. It also could generate single PWM output on the selectable PIC18F14K50 pins when it configured in pulse steering mode. In this tutorial we will take advantage of PIC18F14K50 pulse steering mode to drive the DC Motor and at the same time we will build the RPM (Rotation per Minute) counter to observe the PWM effect on the DC Motor speed and display it on the 2×16 LCD.

The PWM and RPM Counter Project

On this project we will use the HITEC C PRO PIC18 MCU Family Version 9.63PL3 and Microchip MPLAB IDE version 8.40 as our development tools platform. This project also serves as the learning tools of how to use many of the Microchip PIC18 advanced peripherals simultaneously to accomplish the project goal. You could see the complete project demonstrated on the video at the end of this tutorial; Ok now let’s list down all the project interesting features:

- Using Advanced 8-bit Microchip PIC18F14K50 microcontroller with PICJazz 20PIN development board

- Driving the HD44780U 2×16 LCD in 4-bit data mode

- Use DC Motor taken from discarded dual shock PS2 Playstation joystick and the Tamiya racing car tire for measuring the DC Motor RPM

- Simple and easy to build RPM sensor with the infra red reflective object sensor

- Use the ADC peripheral to read the trimport value for adjusting the DC Motor Speed and display the PWM duty cycle on the LCD

- Use the PIC18F14K50 external interrupt and 16-bit TIMER0 counter to measure the RPM and display it on the LCD.

The following is the C code that makes this thing happens:

/* *************************************************************************** ** File Name : pwmrpm.c ** Version : 1.0 ** Description : PIC18 Pulse Width Modulation with RPM Counter ** Author : RWB ** Target : PICJazz 20PIN Board: PIC18F14K50 ** Compiler : HI-TECH C PRO PIC18 MCU Family(Lite) Version 9.63PL3 ** IDE : Microchip MPLAB IDE v8.40 ** Programmer : PICKit2 ** Last Updated : 28 Nov 2009 ** ***************************************************************************/ #include <pic18.h>

/* ** PIC18F14K50 Configuration Bit: ** ** FCMDIS - Fail-Safe Clock Monitor disabled ** CPUDIV_0 - No CPU System Clock divide ** RCIO - Internal RC Oscillator ** PLLDIS - PLL is under software control ** ---------------------------------------------------------------------- ** BORDIS - Brown-out Reset disabled in hardware and software ** WDTDIS - WDT is controlled by SWDTEN bit of the WDTCON register ** ---------------------------------------------------------------------- ** MCLREN - MCLR pin enabled, RE3 input pin disabled ** ---------------------------------------------------------------------- ** XINSTDIS - Disable extended instruction set (Legacy mode) ** LVPDIS - Single-Supply ICSP disabled */

__CONFIG(1, FCMDIS & CPUDIV_0 & RCIO & PLLDIS); __CONFIG(2, BORDIS & WDTDIS); __CONFIG(3, MCLREN); __CONFIG(4, XINSTDIS & LVPDIS); __CONFIG(5, 0xFFFF); __CONFIG(6, 0xFFFF); __CONFIG(7, 0xFFFF);

// LCD Definition #define LCD_HOME 0x02 #define LCD_NEXT_LINE 0xC0 #define LCD_CLEAR 0x01 #define LCD_1CYCLE 0 #define LCD_2CYCLE 1

// RPM Counter Variable

volatile unsigned int rpm_value;

char sdigit[6]={'0','0','0','0','0','\0'};

/* Delay Function */

#define FOSC 16000000UL // Using Internal Clock of 16 MHz

#define delay_us(x) { unsigned char _dcnt; \

_dcnt = (x)/(24000000UL/FOSC)|1; \

while(--_dcnt != 0) continue; \

}

void delay_ms(unsigned int cnt)

{

unsigned char i;

do {

i = 5;

do {

delay_us(164);

} while(--i);

} while(--cnt);

}

// PIC18 High-priority Interrupt Service

void interrupt high_isr(void){

static unsigned char pulse_state=0;

unsigned int rpm_timer;

if (TMR0IF) { // Check for TIMER0 Overflow Interrupt

rpm_value = 0; // Reset the RPM Value

TMR0IF=0; // Clear TIMER0 interrupt flag

}

if (INT0IF){ // Check for External INT0 Interrupt

switch(pulse_state) {

case 0: // First Low to High Pulse

TMR0H = 0; // Zero the high byte in TMR0H Buffer

TMR0L = 0; // Clear 16-bit TIMER0 Counter

pulse_state=1;

break;

case 1: // Second Low to High Pulse

rpm_timer=TMR0L; // Get the first 8-bit TIMER0 Counter

rpm_timer+=(TMR0H << 8); // Get the last 8-bit TIMER0 Counter

// Calculate RPM = 60 x (1/Period)

// RPM Value = 60000 (1 / (0.032 ms x rpm_timer))

rpm_value = (int) (60000.0 / (0.032 * rpm_timer));

pulse_state=0;

}

INT0IF = 0; // Clear INT0 interrupt flag

}

}

/*

** LCD Routine

** LCD Data RB7,RB6,RB5,RB4

** LCD Control: RC7 -> E-Enable, RC6 -> RS-Register Select, R/W-Always 0

*/

void LCD_putcmd(unsigned char data,unsigned char cmdtype)

{

// Put the Upper 4 bits data

PORTB = data & 0xF0;

RC6=0; // RS = 0

RC7=1; // E = 1

// E=0; write data

RC7=0;

delay_us(1); // Delay 1us for 16 MHz Internal Clock

// cmdtype = 0; One cycle write, cmdtype = 1; Two cycle writes

if (cmdtype) {

// Put the Lower 4 bits data

PORTB = (data & 0x0F) << 4;

RC6=0; // RS = 0

RC7=1; // E = 1

// E=0; write data

RC7=0;

delay_us(1); // Delay 1us for 16 MHz Internal Clock

}

delay_ms(5); // Wait for busy flag (BF)

}

void LCD_putch(unsigned char data)

{

// Put the Upper 4 bits data

PORTB = data & 0xF0;

RC6=1; // RS = 1

RC7=1; // E = 1

// E=0; write data RC7=0; delay_us(1); // Delay 1us for 16 MHz Internal Clock // Put the Lower 4 bits data PORTB = (data & 0x0F) << 4; RC6=1; // RS = 1 RC7=1; // E = 1 // E=0; write data RC7=0; delay_ms(5); // Wait for busy flag (BF) }

void LCD_init(void)

{

// Wait for more than 15 ms after VCC rises to 4.5 V

delay_ms(30);

// Send Command 0x30 LCD_putcmd(0x30,LCD_1CYCLE);

// Wait for more than 4.1 ms delay_ms(8);

// Send Command 0x30 LCD_putcmd(0x30,LCD_1CYCLE);

// Wait for more than 100 us delay_us(200); // Delay 250us for 16 MHz Internal Clock ;

// Send Command 0x30 LCD_putcmd(0x30,LCD_1CYCLE);

// Function set: Set interface to be 4 bits long (only 1 cycle write). LCD_putcmd(0x20,LCD_1CYCLE);

// Function set: DL=0;Interface is 4 bits, N=1; 2 Lines, F=0; 5x8 dots font) LCD_putcmd(0x28,LCD_2CYCLE);

// Display Off: D=0; Display off, C=0; Cursor Off, B=0; Blinking Off LCD_putcmd(0x08,LCD_2CYCLE);

// Display Clear LCD_putcmd(0x01,LCD_2CYCLE);

// Entry Mode Set: I/D=1; Increament, S=0; No shift LCD_putcmd(0x06,LCD_2CYCLE);

// Display On, Cursor Off LCD_putcmd(0x0C,LCD_2CYCLE); }

void LCD_puts(const char *s)

{

while(*s != 0) { // While not Null

if (*s == '\n')

LCD_putcmd(LCD_NEXT_LINE,LCD_2CYCLE); // Goto Second Line

else

LCD_putch(*s);

s++;

}

}

// Implementing integer value from 0 to 65530

char *num2str(unsigned int number,unsigned char start_digit)

{

unsigned char digit;

if (number > 65530) number = 0;

digit = '0'; // Start with ASCII '0'

while(number >= 10000) // Keep Looping for larger than 10000

{

digit++; // Increase ASCII character

number -= 10000; // Subtract number with 10000

}

sdigit[0]='0'; // Default first Digit to '0'

if (digit != '0') sdigit[0]=digit; // Put the first digit

digit = '0'; // Start with ASCII '0'

while(number >= 1000) // Keep Looping for larger than 1000

{

digit++; // Increase ASCII character

number -= 1000; // Subtract number with 1000

}

sdigit[1]='0'; // Default Second Digit to '0' if (digit != '0') sdigit[1]=digit; // Put the Second digit

digit = '0'; // Start with ASCII '0'

while(number >= 100) // Keep Looping for larger than 100

{

digit++; // Increase ASCII character

number -= 100; // Subtract number with 100

}

sdigit[2]='0'; // Default Second Digit to '0' if (digit != '0') sdigit[2]=digit; // Put the Second digit

digit = '0'; // Start with ASCII '0'

while(number >= 10) // Keep Looping for larger than 10

{

digit++; // Increase ASCII character

number -= 10; // Subtract number with 10

}

sdigit[3]='0'; // Default Second Digit to '0' if (digit != '0') sdigit[3]=digit; // Put the Second digit

sdigit[4]='0' + number; return(sdigit + start_digit); }

void main(void)

{

unsigned char motor_stat,duty_cycle;

OSCCON=0x70; /* Select 16 MHz internal clock */

// Initial PORT TRISA = 0x30; // Input for RA4 and RA5 TRISC = 0x01; // Set RC0 as Input, RC<7:1> on PORTC as Output PORTC = 0x00; // Initial Port C TRISB = 0x00; // Set PORTB as Output PORTB = 0x00; // Initial Port B TRISB = 0x00; // Set All on PORTB as Output ANSEL = 0x08; // Set PORT AN3 to analog input ANSELH = 0x00; // Set PORT AN8 to AN11 as Digital I/O

// Initial LCD using 4 bits data interface

LCD_init();

LCD_puts("PICJazz 20-PIN\n");

// Init ADC ADCON0=0b00001101; // ADC port channel 3 (AN3), Enable ADC ADCON1=0b00000000; // Use Internal Voltage Reference (Vdd and Vss) ADCON2=0b00101011; // Left justify result, 12 TAD, Select the FRC for 16 MHz // Init TIMER0: Period: 4 x Tosc x Prescale for each counter // Tosc = 1/16 Mhz = 0.0000000625 // TIMER0 Period: 4 x 0.0000000625 x 128 = 0.000032 Second = 0.032 ms T0CON = 0b10000110; // TIMER0 Enable, use 16-bit timer and prescale 1:128 TMR0H = 0; // Zero the high byte in TMR0H Buffer TMR0L = 0; // Clear 16-bit TIMER0 Counter TMR0IE = 1; // Enable TIMER0 Overflow Interrupt

// Set the External Interrupt on INT0 (RC0) Port INT0IE = 1; // Enables the INT0 external interrupt INTEDG0 = 1; // Interrupt on rising edge // Init PWM for Single Output CCP1CON=0b00001100; // Single PWM mode; P1A, P1C active-high; P1B, P1D active-high CCPR1L=0; // Start with zero Duty Cycle PSTRCON=0b00000100; // Enable PIC Pulse Steering PWM on RC3 Port

// PWM Period = 4 x Tosc x (PR2 + 1) x TMR2 Prescale Value // Tosc = 1/16 Mhz = 0.0000000625 // PWM Period = 4 x 0.0000000625 x 201 x 4 = 0.000201 // PWM Frequency = 1/PWM Period = 1/0.000201 = 4.975 kHz T2CON=0b00000101; // Postscale: 1:1, Timer2=On, Prescale = 1:4 PR2=200; // Frequency: 4.975 kHz TMR2=0; // Start with zero Counter // Initial Variable used rpm_value=0; motor_stat=0; // Motor Off Condition duty_cycle=0; // 0 Duty Cycle

// Now Enable the Interrupt IPEN = 1; // Enable High Priority Interrupt GIEH = 1; // Global Interrupt Enable (High Priority)

for(;;) {

if (RA5 == 0) { // Read Switch

delay_ms(1);

if (RA5 == 0) { // Read again for Simple Debounce

motor_stat ^= 0x01;

}

}

if (motor_stat) {

GODONE=1;

while (GODONE) continue; // Wait conversion done

duty_cycle=ADRESH; // Get the High byte ADC 8-bit result

} else {

duty_cycle=0;

}

// Assign duty cycle to the PWM CCPR1L register

CCPR1L = duty_cycle;

// Display the Information on the LCD

LCD_putcmd(LCD_HOME,LCD_2CYCLE); // LCD Home

LCD_puts("Duty Cycle: "); LCD_puts(num2str((int)((duty_cycle/255.0) * 100.0),3));

LCD_puts(" %");

LCD_putcmd(LCD_NEXT_LINE,LCD_2CYCLE); // Goto Second Line

LCD_puts("RPM: "); LCD_puts(num2str(rpm_value,1));

// Put the delay here

delay_ms(10);

}

}

/* EOF: pwmrpm.c */

The PIC18 Pulse Steering PWM mode

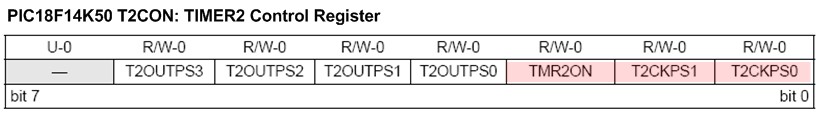

The heart of the PIC18F14K50 pulse steering PWM mode is rely on the TIMER2 peripheral, where it used as the basic counter generator for the PWM signal. The TIMER2 counter clock (TMR2) is supplied by selectable prescale clock, this prescale circuit will divide the system clock by 1, 4 or 16 respectively. The prescale could be selected by assigning the T2CKPS1 and T2CKPS0 bits in the T2CON register.

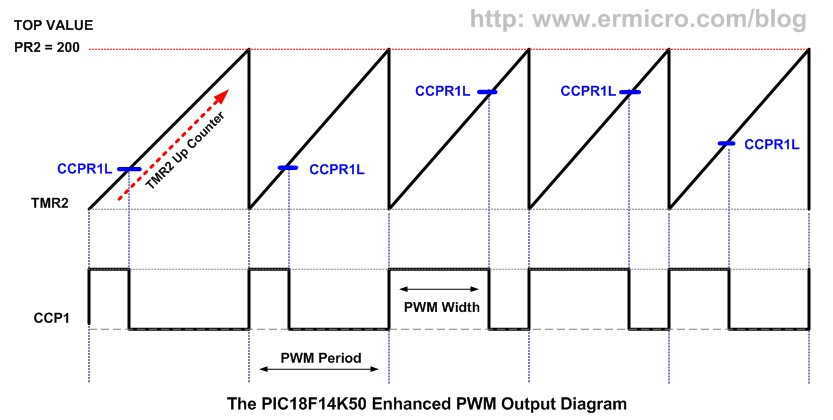

The TMR2 register value is continuously compared to the PR2 register which determine the TOP value of the TMR2 counter register. When the TMR2 register value reach the PR2 value, then the TMR2 counter register value will be reset to 0.

At the same time the value of TMR2 counter register is also being compared to the CCPR1L register value (actually with the CCPR1H register value, since the CCPR1H equal to CCPR1L than we could say CCPR1L), when the TMR2 reach the CCPR1L value than the PWM peripheral circuit will reset the CCP1 output (logical “0“) and when the TMR2 counter register equal to the PR2 register value than it will set the CCP1 output (logical “1“). Therefore by changing the PR2 value we could change the PWM period and this mean changing the PWM frequency as well. The PWM period could be calculated using this following formula:

PWM period = 4 x Tosc x ( PR2 + 1) x (TMR2 prescale value) second

Where Tosc is the system clock period in second

PWM frequency = 1 / PWM Period Hz

By assigning the PR2 register with 200 and select the prescale to 4; and applying all these values to the formula above, we could determine the PWM frequency for our DC Motor base on the internal system oscillator of 16 MHz as follow:

PWM period = 4 x (1 / 16.000.000) x 201 x 4 = 0.000201 second

Therefore the PWM frequency is:

PWM frequency = 1 / 0.000201 = 4.975 kHz

The T2CON (TIMER2 Control) register is used select the postscale (T2OUTPS<3:0>), activate the TIMER2 peripheral (TMR2ON) and set the prescale clock used by the TMR2 counter register. BY setting the T2CKPS1=0 and T2CKPS0=1 in the T2CON register we select the 1:4 prescale; and by setting the TMR2ON to logical “1” we activate the TIMER2 peripheral.

The following is the C code to initialize the TIMER2 peripheral:

// PWM Period = 4 x Tosc x (PR2 + 1) x TMR2 Prescale Value // Tosc = 1/16 Mhz = 0.0000000625 // PWM Period = 4 x 0.0000000625 x 201 x 4 = 0.000201 // PWM Frequency = 1/PWM Period = 1/0.000201 = 4.975 kHz T2CON=0b00000101; // Postscale: 1:1, Timer2=On, Prescale = 1:4 PR2=200; // Frequency: 4.975 kHz TMR2=0; // Start with zero Counter

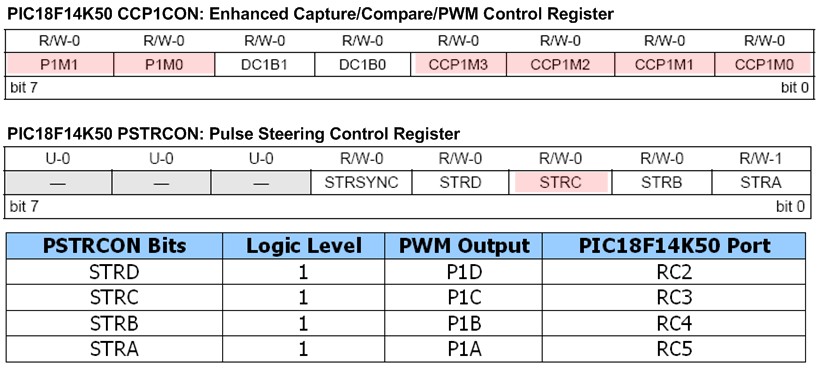

By setting P1M1=0 and P1M0=0 bits in the CCP1CON register we select the single output PWM; setting the CCP1M3=1, CCP1M2=1, CCP1M1=0 and CCP1M0=0 in the CCP1CON register we select the PWM mode with P1A, P1C active-high; P1B, P1D active-high.

On this tutorial we just set the additional 2 LSB extended bits (DC1B1 and DC1B0) to all zero (logical “0“) for the CCPR1L register (10-bit wide). We start by setting the CCPR1L to zero mean we start with zero duty cycle (no PWM output yet). In single PWM mode we could select the PWM output to PIC18F14K50 RC3 output port by setting the STRC bit on PSTRCON (Pulse Steer Control) register to the logical “1” while other bits is set to logical “0“. The following is the C code:

// Init PWM for Single Output CCP1CON=0b00001100; // Single PWM mode; P1A, P1C active-high; P1B, P1D active-high CCPR1L=0; // Start with zero Duty Cycle PSTRCON=0b00000100; // Enable PIC Pulse Steering PWM on RC3 Port

By applying the analog value read from the 10K trimport connected to the PIC18F14K50 RA4 pins, we could easily varying the PWM duty cycle by changing the voltage divider output formed by the 10K trimport. The following C code shows how we use the PIC18F14K50 microcontroller ADC peripheral to change the PWM duty cycle; for more information about using the ADC peripheral on PIC18 families you could read my previous posted blog PIC18 Microcontroller Analog to Digital Converter with Microchip C18 Compiler:

// Init ADC ADCON0=0b00001101; // ADC port channel 3 (AN3), Enable ADC ADCON1=0b00000000; // Use Internal Voltage Reference (Vdd and Vss) ADCON2=0b00101011; // Left justify result, 12 TAD, Select the FRC for 16 MHz ... ...

if (motor_stat) {

GODONE=1;

while (GODONE) continue; // Wait conversion done

duty_cycle=ADRESH; // Get the High byte ADC 8-bit result

} else {

duty_cycle=0;

}

// Assign duty cycle to the PWM CCPR1L register

CCPR1L = duty_cycle;

The enhanced PWM feature on the PIC18 families actually is almost identical to the PIC16 families series, therefore you could read more about the enhanced PWM feature if you want to drive the H-bridge DC motor circuit from my previous posted blog H-Bridge Microchip PIC Microcontroller PWM motor Controller.

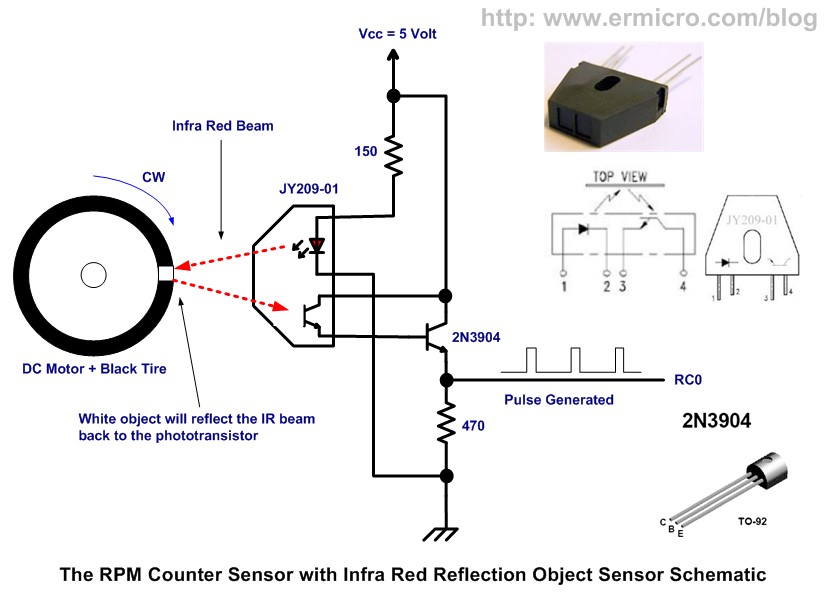

The RPM Sensor

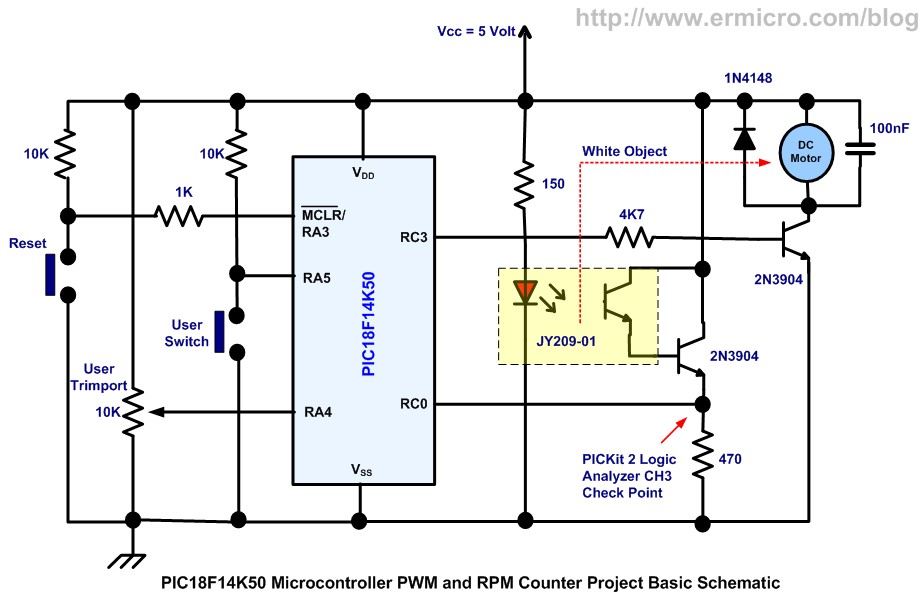

To count the DC motor rotation per minute (RPM), I decided to use the infra red reflective object sensor Junye JY209-01 or you could replace it with Fairchild QRE00034; as this type of sensor will make sensing the DC motor rotation become easier.

The infra red reflective object sensor work by simply emitting the infra red beam and when it encounter the white object surface than the infra red beam will be reflected back to the phototransistor; next the phototransistor and the 2N3904 transistor which formed the Darlington pair will start to conduct and will generate enough voltage across the 470 Ohm resistor to be considered by the PIC18F14K50 microcontroller build in Schmitt trigger RC0 input port as the logical “1“. When the infra red beam encounters the black tire surface than both of the phototransistor and 2N3904 transistor will turn off; and the voltage across 470 Ohm resistor will drop to zero volt (logical “0“).

Therefore by timing the generated pulse period by the infra red reflective object sensor we could easily calculate the RPM using this following formula:

Frequency = 1/T Hz; T is the generated pulse period in second.

RPM (Rotation per Minute) = Frequency x 60

The following pictures show in detail of how I put the PS2 Playstation dual shock DC motor, the Tamiya racing car tire with the white sticker and the infra red reflective object sensor for this project.

The PIC18 External Interrupt

As I mention before that in order to calculate the DC motor RPM, we could simply calculate the period of the pulse generated by the RPM sensor shown above. One of the methods to measure the pulse period is to use the PIC18F14K50 microcontroller ECCP (Enhanced Capture/Compare/PWM) peripheral in the capture mode to calculate the period; in the capture mode we could easily use the 16-bit TIMER1 or TIMER3 to count the pulse period by feeding the pulse directly to the CCP1 pins (RC5). The capture interrupt will be generated every rising edge of the pulse (or falling edge), therefore by knowing the exact TIMER1 or TIMER3 counter clock time period and get the timer 16-bit counted value between the two rising edge pulse we could calculate the RPM.

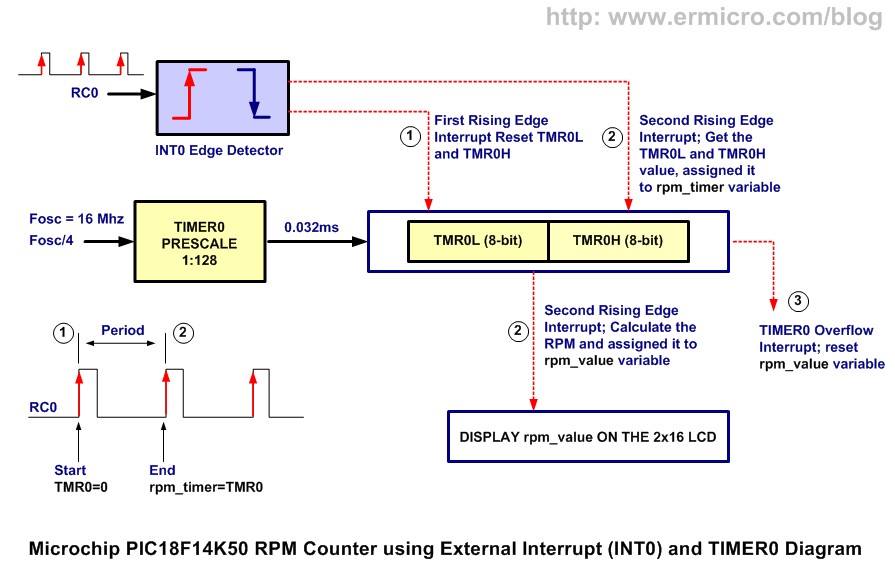

Unfortunately we could not use the Microchip PIC18F14K50 microcontroller ECCP peripheral as this peripheral has already being used to generate the PWM signal for the DC motor in our project, but using the same principal we could make use of the PIC18F14K50 external interrupt peripheral on pin INT0 (RC0) or INT1 (RC1). This external interrupt peripheral will generate interrupt on every rising edge (or falling edge) of the pulse; therefore by combining it with the 16-bit TIMER0 counter mode now we could calculate the RPM as shown on the following diagram.

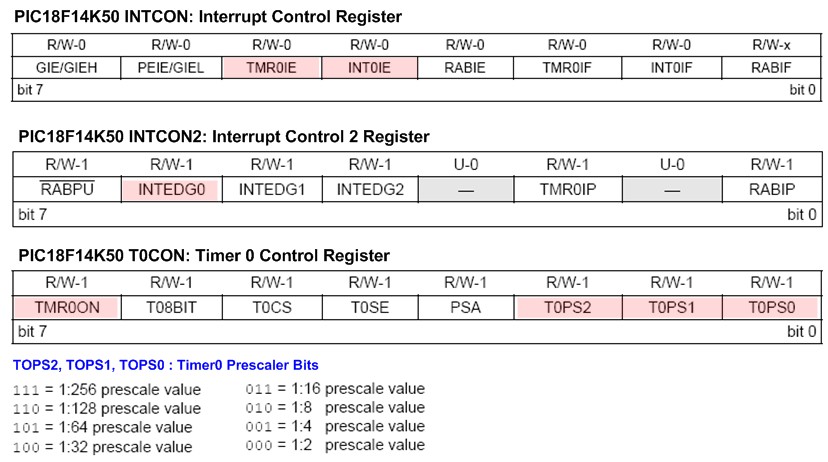

As shown on the above picture, first we have to activate the PIC18F14K50 microcontroller external interrupt and configure it to detect the pulse rising edge; next we configure the TIMER0 peripheral for the RPM period counter.

By setting the TMR0E and INT0IE bits to logical “1” on the PIC18F14K50 microcontroller interrupt control register (INTCON) and TMT0ON bits to logical “1” on the TIMER0 control register (T0CON), we activate both the TIMER0 and External peripherals. Selecting the 1:256 prescale value we could calculate the time required to increase the TIMER0 16-bit counter.

TIMER0 Clock period = 4 x Tosc x TMR2 prescale value second

TIMER0 Clock period = 4 x (1/16.000.000) x 128 = 0.000032 second = 0.032 ms

This mean the TIMER0 counter required 0.032 ms to increase the TMR0L and TMR0H registers counter value by one. The following C code shows the PIC18F14K50 microcontroller external interrupt and TIMER0 peripherals initialization:

// Init TIMER0: Period: 4 x Tosc x Prescale for each counter // Tosc = 1/16 Mhz = 0.0000000625 // TIMER0 Period: 4 x 0.0000000625 x 128 = 0.000032 Second = 0.032 ms T0CON = 0b10000110; // TIMER0 Enable, use 16-bit timer and prescale 1:128 TMR0H = 0; // Zero the high byte in TMR0H Buffer TMR0L = 0; // Clear 16-bit TIMER0 Counter TMR0IE = 1; // Enable TIMER0 Overflow Interrupt

// Set the External Interrupt on INT0 (RC0) Port INT0IE = 1; // Enables the INT0 external interrupt INTEDG0 = 1; // Interrupt on rising edge

By setting the INTEDG0 to logical “1” on INTCON2 (interrupt Control 2) register we choose the Rising Edge detection. The RPM value is being calculated inside the interrupt service routine as shown on this following C code:

// PIC18 High-priority Interrupt Service

void interrupt high_isr(void){

static unsigned char pulse_state=0;

unsigned int rpm_timer;

if (TMR0IF) { // Check for TIMER0 Overflow Interrupt

rpm_value = 0; // Reset the RPM Value

TMR0IF=0; // Clear TIMER0 interrupt flag

}

if (INT0IF){ // Check for External INT0 Interrupt

switch(pulse_state) {

case 0: // First Low to High Pulse

TMR0H = 0; // Zero the high byte in TMR0H Buffer

TMR0L = 0; // Clear 16-bit TIMER0 Counter

pulse_state=1;

break;

case 1: // Second Low to High Pulse

rpm_timer=TMR0L; // Get the first 8-bit TIMER0 Counter

rpm_timer+=(TMR0H << 8); // Get the last 8-bit TIMER0 Counter

// Calculate RPM = 60 x (1/Period)

// RPM Value = 60000 (1 / (0.032 ms x rpm_timer))

rpm_value = (int) (60000.0 / (0.032 * rpm_timer));

pulse_state=0;

}

INT0IF = 0; // Clear INT0 interrupt flag

}

}

By resetting the TIMER0 counter on the first rising edge external interrupt and reading back the TIMER0 counter on the second rising edge external interrupt we could easily calculate the pulse period

Pulse Period = 0.032 x TIMER0 Counter (TMR0H:TMR0L) millisecond

The RPM value is the frequency of rotation measured in minute (60 second), therefore the DC motor RPM value could be calculated as the following formula:

rpm_value = (1 / Pulse Period) in second x 60 = 60000.0 / 0.032 x rpm_timer

The rpm_timer variable contains the 16-bit TIMER0 counter value, while the global rpm_value contain the RPM value of the DC motor.

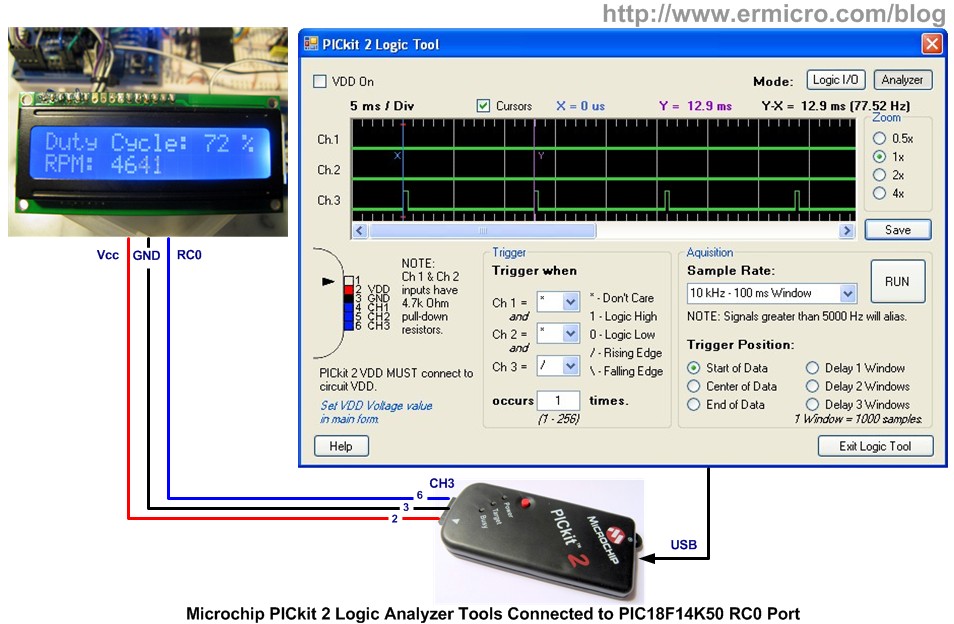

The PICKit2 Logic Analyzer

To check the RPM counter accuracy I simply use one of the useful feature of the Microchip PICKit2 programmer, where we could use it as the powerful Logic Analyzer tools to debug serial communication buses such as UART, SPI and I2C. This time we will use it to analyze the RPM pulse produce by the infra red reflective object sensor circuit above and connected the output directly to the PIC18F14K50 microcontroller RC0 input port and the PICKit2 channel 3 inputs to measure the RPM pulse period.

The PICKit2 Logic Analyzer tool could be used by running the PICKit2 programmer Version v2.61 and selecting the Logic Tools from the Tools menu; set the Rising Edge trigger on the channel 3 and 100 ms Sample Rate; next press the RUN button. After the pulse appears check the Cursor checkbox to activate the X and Y horizontal bar to measure the pulse period.

As shown on the above picture, the channel 3 on the PICKit2 logic analyzer tool show that the measured pulse frequency is about 77.52 Hz; this mean the RPM is about 4651 (77.52 x 60) which is close enough to the RPM calculated value 4641 displayed on the LCD at 72% PWM duty cycle.

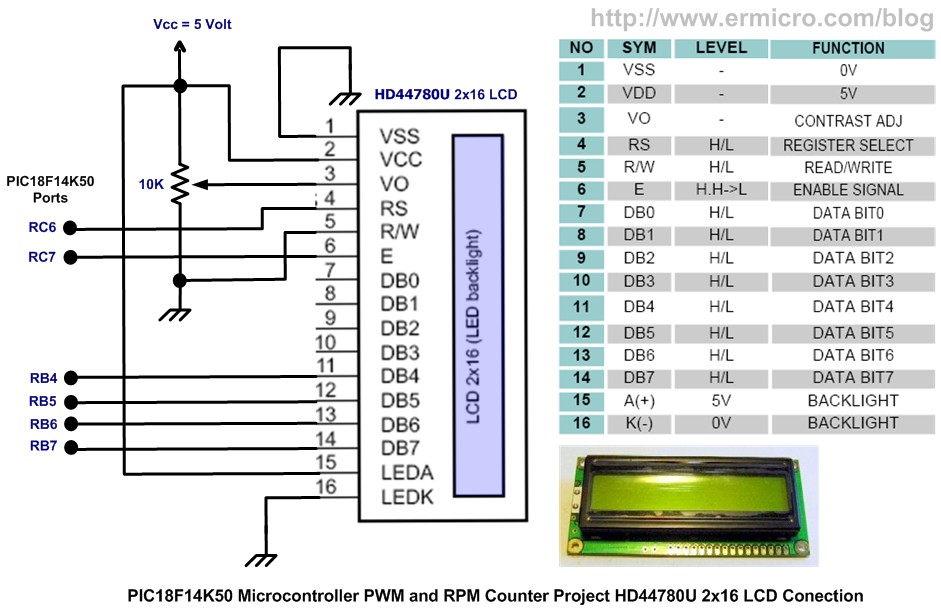

The 2×16 LCD Display

To display both of the PWM duty cycle and RPM value, I used the Hitachi HD44780U or the equivalent microcontroller 2×16 LCD with back light LED in 4-bit data mode. Most of the LCD function C routine I use in this project is taken from my previous posted blog AVR LCD Thermometer Using ADC and PWM Poject; where you could read more information about the principal of how to drive this kind of display. The following is the list of C function for driving the LCD:

- LCD_putch() function is used to display single character on the LCD

- LCD_putcmd() function is used to send LCD command (e.g. clear the LCD, move to second row, etc)

- LCD_init() function is used to initialized the 2×16 LCD; this function will initialized the 2×16 LCD into 4-bit data mode

- LCD_puts() function is used to display a string on the LCD

- num2str() function is used to convert a numeric value to a string, we use this function to display numeric value on the LCD.

Inside the C Code

The C program begins by selecting the 16 MHz internal clock and setting all the I/O ports used on this project. After doing the LCD, ADC, TIMER0, External Interrupt and PWM/TIMER2 peripherals setup. After enabling the high priority interrupt and activating the global interrupt the code enter the for(;;) endless loop. Inside this loop; first we read the user’s switch, this switch is attached to the PIC18F14K50 microcontroller input port RA5 and work as the toggle switch to run or stop the DC motor:

if (RA5 == 0) { // Read Switch

delay_ms(1);

if (RA5 == 0) { // Read again for Simple Debounce

motor_stat ^= 0x01;

}

}

The PIC18F14K50 microcontroller ADC peripheral than read the analog input on channel 3 (RA4) port and assigned the value to the CCPR1L register where it used to control the PWM duty cycle.

if (motor_stat) {

GODONE=1;

while (GODONE) continue; // Wait conversion done

duty_cycle=ADRESH; // Get the High byte ADC 8-bit result

} else {

duty_cycle=0;

}

// Assign duty cycle to the PWM CCPR1L register CCPR1L = duty_cycle; Then next we display the duty cycle and the RPM value on the 2x16 LCD:

// Display the Information on the LCD

LCD_putcmd(LCD_HOME,LCD_2CYCLE); // LCD Home

LCD_puts("Duty Cycle: "); LCD_puts(num2str((int)((duty_cycle/255.0) * 100.0),3));

LCD_puts(" %");

LCD_putcmd(LCD_NEXT_LINE,LCD_2CYCLE); // Goto Second Line

LCD_puts("RPM: "); LCD_puts(num2str(rpm_value,1));

Downloading and Running the Code

After compiling and simulating your code hook up your PICKit2 programmer to the PICJazz 20PIN development and learning board ICSP port turn power on. From the MPLAB IDE menu select Programmer -> Select Programmer -> Pickit2 it will automatically configure the connection and display it on the PICkit2 tab Output windows; now you are ready to down load the code from MPLAB IDE menu select Programmer -> Program; this will down load the HEX code into the PICJazz 20PIN board with the Microchip PIC18F14K50 microcontroller on it.

Now its time to run your PWM and RPM counter code, where you could enjoy this following video showing all of the process that we’ve been going through.

The Final Though

Obviously the Microchip PIC18 PWM peripheral feature is almost identical to its 8-bit PIC16 little brother families, therefore upgrading from the PIC16 to PIC18 could be done almost without changing the code. In this project we also take advantage of the infra red reflective object sensor to measure the RPM, where we don’t have to make special modification on the wheel in order to make this sensor to sense the rotation; all we need is just a piece of white sticker attached to the wheel.

This project also shows us an example of how we use many of the advanced PIC18F14K50 microcontroller peripherals at the same time, which will help to shape our understanding of how we could utilize all of these peripherals in the future project.

Bookmarks and Share

Related Posts

30 Responses to “PIC18 Pulse Width Modulation (PWM) DC Motor Speed Controller with the RPM Counter Project”

Comment by rwb.

For this project I program it only on C language not assembler, but if you familiar with the PIC assembler you could use similar principle to manipulate the PIC microcontroller registers as described on this blog. As I also use direct register manipulation to achieve this project purpose (i.e. PWM and ADC).

Comment by lawrence.

well i have tried to change tmr0 as it is 16-bit on the 18f but 8-bit on the 16f etc so do you mind if you can post a C code but this using the famous outdated 16f877a please help me out as I am struggling to get it right using the pic 16f877 believe me i have manipulated the timer and ADC to 10 bit and did the justification but still struggling.

Comment by rwb.

My suggestion is to try the microcontroller peripherals once at the time start with the ADC then continue with the PWM, External Interrupt and TIMER0.

Comment by embed84.

Hi i am a student embedded systems, and i’m working on my first microchip project 🙂 cool, i wonder if i can use the

void interrupt high_isr(void); function on a pic18f4550 to read the rotation of my robot wheels. i’m using two QSE113 transistors. the pulses will be used to make a rotation of 45 degrees. is it possible?

Comment by rwb.

Although its possible to do that but for controlling DC motor for fix 45 degree rotation will be quite hard as you need to apply special circuit and logic for the DC motor break system. For precision position its better to use the DC stepper motor.

Comment by wangui_esther.

hello. am very new to this site, and i can’t believe what i was missing.

Anyway, i want to do a small project so am doing a bit of research.I want to move a machine table which will have two axes, x and y. And i will require to control the speed of the motors for the two axes.

what am wondering , so far like in this tutorial, the motors are very small in size. obviously my application will require a stronger motor. what kind of micro controllers can i use for such? and do i use atmel’s microcontrollers or PICs? thanks

Comment by rwb.

You could use Atmel AVR or Microchip PIC, because both of this microcontrollers could be use to control the DC motor speed with their PWM feature.

Comment by wangui_esther.

hi, rwb. the particular motor available to me is the stepper motor from RS labelled RS 34-3755 4.3A/PH.

Is it possible for PIC18F14K50 to drive this motor since in this tutorial you use a much smaller motor?

Also you have worked with dc motors and the servo motor from the blogs i’ve seen. is it possible to control the speed of a servo motor using the micro controller’s pwm facility? I am asking so i can know what microcontroller and programmer to buy. Thanks

Comment by rwb.

The stepper motor is different from the ordinary DC motor, therefore to drive the stepper motor you have to use different circuit and logic. When you want to drive a bigger DC motor just change the motor driver circuit and using the Darlington Transistor or better use the high current MOSFET. The PIC18F14K50 microcontroller practically could drive any kind of motor but we have to use a suitable motor driver circuit in order do it. For more information of how to drive bigger current you could read my previous posted blog “Using Transistor as Switch” (http://www.ermicro.com/blog/?p=423).

The standard servo motor usually has a fixed speed, we only can control the servo motor direction through PWM not the speed. For more information of how to drive the servo motor, you could read my previous posted blog “Basic Servo Motor Controlling with Microchip PIC Microcontroller” (http://www.ermicro.com/blog/?p=771)

Comment by wangui_esther.

Thanks so much rwb. I am definitely going to be needing advice on coding for stepper motors. But i am going to try out with dc motors first Oonce i get all the equipment together so i’ll at least have a clue on working with microcontrollers. Something i meant to ask is, is it possible to vary the speed of stepper motors and is it possible to achieve positional accuracy with dc motors say move it by 150 cm then stop?

Comment by rwb.

Yes you could vary the speed of stepper motor, remember that the stepper motor torque will decrease as it speed increase. Yes you could achieve quite accurate position by adding the wheel encoder to the DC motor.

Comment by wangui_esther.

hi rwb. now, i have an atmega 64 chip, avr studio, an stk 500 programmer and stepper motor RS 34-3755 4.3A/PH. i want to make the motor move and control its speed. the thing is i have never built any circuit before and apart from the examples in the internet i have not written any code. where do i start?

Comment by rwb.

The first thing you need is a good reference for the stepper motor, fortunately Atmel has a good application note and the example code for it (AVR446: Linear speed control of stepper motor); then you have to start to program your AVR microcontroller with a simple application such as the blinking LED in order to get acquainted with the AVR development environment, you could read my previous posted blog “Using Transistor as Switch” (http://www.ermicro.com/blog/?p=423) for the example. The next step build your stepper motor driver circuit and program the AVR to rotate this stepper motor.

Comment by wangui_esther.

thanks. i will do just that.

Comment by iriana.

Hii rbw, I’m doubt and curious so I would like to ask in this case of the rpm sensor. Will the diameter of the wheel affect the rpm value? Likewise, larger wheel will have a lower rpm value compared to that is by smaller wheel? Due to the every beam received by the photo-transistor with diffs circumference of the wheel.

If it is yes, so what do you think for getting the ‘real’ RPM value of a motor? Thank you so much if you would like to give me some advices 🙂

Comment by rwb.

No, the diameter of the wheel won’t effect the rpm value measured by the sensor. Since we simply count the white marker (i.e. the white sticker) received by the photo-reflector sensor from one complete rotation of the wheel (1 rotation = 1 pulse).

Comment by iriana.

Thank you rwb.

Comment by aor777.

Hi,

As per the PIC 18F14K50 datasheet it can support 4 channel PWM. what i learn from your tutorial is that all the four channels will output identical PWM waveform. Please correct me if i am wrong. Also, tell me how to output 4 different PWM signals controlled using 4 different potentiometers. Thanks in advance.

Comment by rwb.

The datashet didn’t mention 4 channels, but it say 4 PWM outputs from one Enhanced Capture/Compare/PWM (ECCP) module. This ECCP module is specially designed for controlling the H-Bridge motor. To have 4 different PWM output with 4 potentiometers you need to have 4 independent PWM generator.

Comment by muslihen19.

Hi rwb,

where can i download HI-TECH C PRO PIC18 MCU Family(Lite) Version 9.63PL3 compiler, can u give the link? i already compile it using HC PIC18-Lite-9.66 but it still got error

Comment by rwb.

You should be able to compile the project using Microchip HI-TECH C Compiler for PIC18 MCU Lite (free version) which you could download it from Microchip official website (www.microchip.com).

Comment by David.

This is an excellent tutorial Mr. RWB. I thank you. It is tempting to wish for a recipe that fills every need exactly, but then we do not learn. Your tutorials are far more than a recipe. I appreciate very much how well written they are.

One question: In the Project Basic schematic above, you show a resistor labeled “4K7.” I am not familiar with that notation for resistors (I have seen it elsewhere in your tutorials). Do you mean 47K? Or…?

This is good stuff man, you have made my day.

Comment by JamTheMan.

Hi rwb,

I was wondering if it was possible to change the direction of rotation of the DC Motor using this design.

And if there is another way of driving the motor other than using an H-Bridge?

Thanks in advance.

Comment by rwb.

In order to change the DC motor direction you need to change the DC motor power supply polarity, the H-Bridge is the circuit that could do this function. If you don’t want to use the H-Bridge circuit, You could use a simple DPDT (Double Pole Double Through) relay to do this function and you only need 1 transistor and 1 output port to change the DC motor direction.

Comment by JamTheMan.

I will check the DPDT out, sounds promising.

Thanks again rwb. This post has been such a great help.

Comment by kik0.

Hi I have to Control DC motor whit PIC18f8490 and i have one question. My PIC has a LCD Driver. The motor’s senzor for RPM product 2500 pulses on one turnig on the rotor. I undurstand how to set the timer on counter mode and count pulses but how can I turn them in RPM and show them on the displey. It’s i litle hard to me. The displey is https://www.olimex.com/Products/_resources/LCD/LCD-449STK2.pdf Thanks

Comment by rwb.

You could get an idea from this project PIC18 Pulse Width Modulation (PWM) DC Motor Speed Controller with the RPM Counter Project.

Comment by kik0.

And one more question 🙂 how can i make to stop and start the motor whit one button 🙂

Comment by lawrence.

Hi I would appreciate it if you could send the code in assembly (*.asm ) as i am not familiar c or if there is a method to change the code then i would appreciate it and i am using the pic 16f887A mplab v8.1 using a bootloader connected via rs232.

please help me out